11 Ways to Improve Your Business Processes (With Practical Examples)

Running the same workflows day after day makes it tempting to stick with "the way things have always been done." But taking time to refine how your team works can dramatically boost efficiency, cut costs, and reduce costly mistakes.

In this guide, we'll explore practical ideas for improving your business processes and look at how modern tools can help put them into action.

What Exactly Is Process Improvement?

Process improvement means examining your existing workflows, finding what's holding them back, and making targeted changes to get better results. The aim is straightforward: optimise how work gets done so your team produces higher quality output with less friction.

When done well, process improvement helps you generate better work, reduce the fallout from human error, eliminate wasteful steps, speed up project completion, and remove the friction that slows everything down.

Why Bother Improving Your Processes?

Before diving into specific strategies, it's worth understanding what you stand to gain.

Greater productivity. Research shows the average worker spends roughly 520 hours each year on repetitive tasks that could be automated. Reclaiming even a fraction of that time lets your team focus on work that actually moves the needle.

Happier customers. Better processes mean faster responses, fewer errors, and more consistent quality—all things that translate directly into customer satisfaction.

More engaged employees. When people aren't bogged down with tedious busywork, they can channel their energy into creative problem-solving and strategic thinking. That shift alone can transform workplace morale.

Lower risk. Streamlined processes bring better visibility and control, reducing exposure to compliance issues, security gaps, and operational blind spots.

11 Ways to Improve Your Processes

1. Track Time and Analyse Where It Goes

At the core of every process are the people doing the work. Understanding how time is actually spent—rather than how you assume it's spent—reveals opportunities you'd otherwise miss.

Modern time tracking tools can generate automatic timesheets, provide clear records of work completed, and surface patterns in how hours are allocated. The goal isn't micromanagement; it's giving teams visibility into their own productivity so they can make smarter choices.

2. Monitor Team Performance

While time tracking shows immediate activity, monitoring overall performance helps you spot bottlenecks before they become crises. Project status tracking makes it clear where work is getting stuck and who might need support.

The right tools can surface these insights automatically, alerting managers when workloads become unbalanced or deadlines are at risk.

3. Create Clear Project Management Processes

Most business processes are repetitive by nature. Defining clear phases for how projects move from start to finish ensures everyone knows what's expected at each stage. Mapping out workflows visually—with assigned roles and responsibilities—prevents tasks from falling through the cracks.

4. Strengthen Communication

Poor communication between teams is one of the biggest process killers. Important details get lost, decisions stall, and work gets duplicated. Investing in tools that centralise collaboration and keep everyone aligned eliminates much of this friction.

5. Identify and Eliminate Waste

A core principle of process improvement is finding and removing waste. This includes unnecessary processing steps, redundant reporting, inventory that sits unused, work that has to be redone due to defects, and talent that's not being fully utilised.

Start by observing your current workflows carefully. Where does work sit waiting? What steps don't actually add value? What could be consolidated or removed entirely?

6. Cut Unnecessary Costs

Related to eliminating waste is actively looking for cost reductions. This might mean removing duplicate tasks, automating manual work, or reordering steps so processes flow more logically. Sometimes the biggest savings come from simply asking "why do we do it this way?" and finding there's no good answer.

7. Visualise Your Processes

You can't improve what you can't see. Creating visual maps of your workflows—showing each step, who's responsible, and how long things typically take—makes inefficiencies obvious. Bottlenecks that were invisible suddenly become clear targets for improvement.

8. Focus on Revenue Generation

Process improvement isn't just about cutting costs. It can also drive growth by freeing up capacity to pursue new opportunities, expand into new markets, or deepen relationships with existing customers. When your team isn't drowning in administrative work, they can focus on activities that generate revenue.

9. Raise Quality Standards

Many quality problems trace back to process issues. Errors creep in when steps are unclear, handoffs are messy, or checks get skipped under time pressure. Automating routine tasks reduces human error, while structured workflows ensure nothing gets missed.

When investigating quality issues, try the "5 Whys" technique: keep asking why something happened until you reach the root cause rather than just addressing symptoms.

10. Streamline for Efficiency

Look for redundant work that could be eliminated, meetings that could be emails (or eliminated entirely), approval chains that add delay without adding value, and supply bottlenecks that slow everything down. Often the most impactful improvements come from simply removing unnecessary steps rather than adding new ones.

11. Make Continuous Improvement a Habit

Process improvement isn't a one-time project—it's an ongoing practice. The most effective organisations build regular review cycles into their operations, constantly looking for small refinements that compound over time.

Modern tools make this easier by providing real-time insights into how processes are performing, making it simple to spot opportunities as they emerge.

Real-World Examples of Process Improvement

Improving Data Accuracy

Manual data entry is a constant source of errors. Every mistake costs time to find and fix—sometimes much more if it creates downstream problems. Automation tools that collect, validate, and standardise data can dramatically reduce these errors while freeing up staff for higher-value work.

Reducing Unnecessary Processing

Time spent re-entering information across multiple systems, recreating reports that already exist elsewhere, or manually scanning and filing documents creates bottlenecks and delays. Centralising data and automating routine document handling eliminates much of this waste.

Minimising Wait Time

Processes often stall while waiting for approvals or access to systems. Building automated notification and escalation into your workflows keeps things moving. When someone needs to take action, they're prompted immediately rather than discovering it days later.

Preventing Overproduction

Whether it's manufacturing too much product or generating reports nobody reads, overproduction wastes resources. Understanding what's actually needed—and building processes that produce just that—reduces waste and keeps focus on what matters.

Popular Process Improvement Frameworks

If you're looking for structured approaches to process improvement, several proven methodologies exist.

PDSA (Plan-Do-Study-Act) is a simple cycle: define the problem and potential solutions, implement your chosen approach, analyse the results, then standardise what works.

5S focuses on workplace organisation through five steps: Sort, Set in Order, Shine, Standardise, and Sustain. It's particularly useful for physical workspaces but applies to digital organisation too.

The 5 Whys is a root cause analysis technique. When something goes wrong, asking "why?" repeatedly (typically five times) helps you move past surface symptoms to underlying causes.

Putting Process Improvement Into Practice

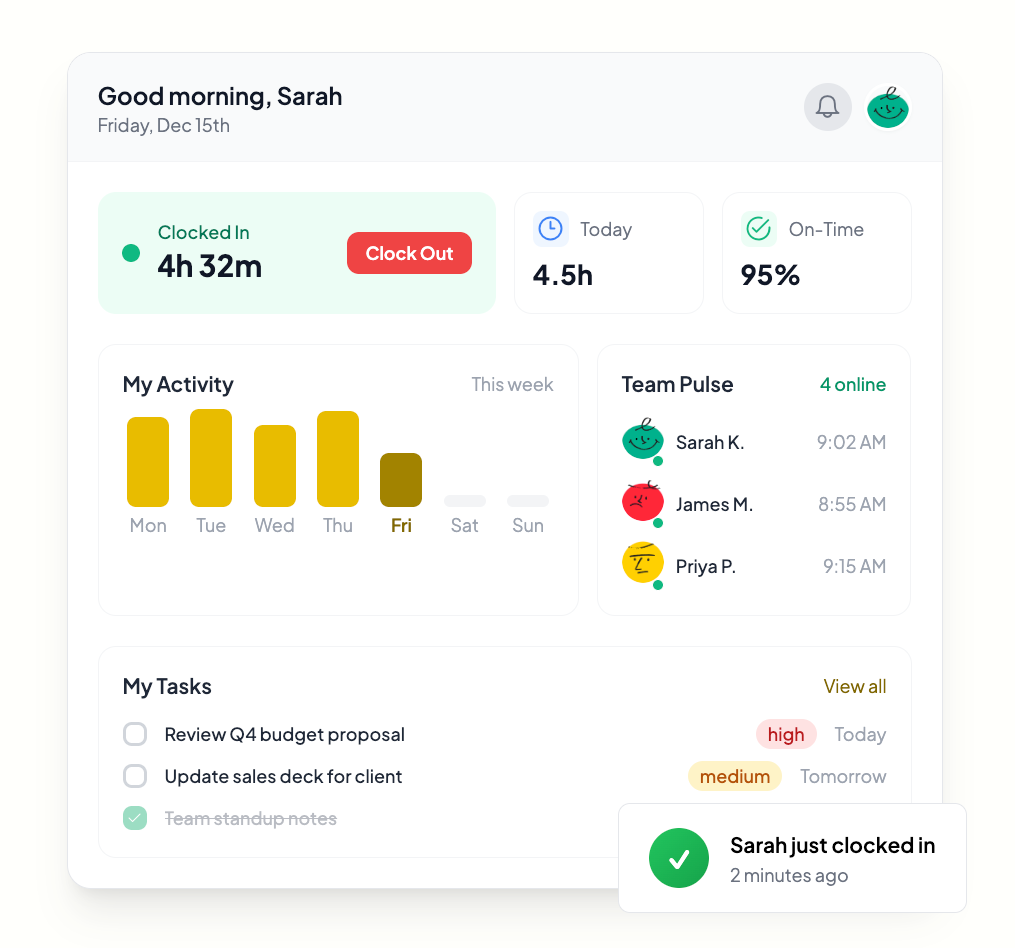

The right technology can accelerate every aspect of process improvement. Modern workplace platforms help you visualise how work currently flows, automate repetitive tasks that consume time, track performance and surface bottlenecks, and provide the data needed for continuous refinement.

For teams ready to tackle process improvement head-on, Asa.Team offers a comprehensive solution that addresses many of the challenges covered in this article. The platform automates time tracking and attendance across web, Microsoft Teams, Slack, and Telegram—eliminating manual timesheets entirely and providing real-time visibility into how your team's hours are spent. Its AI-powered workflow automation helps streamline repetitive processes, while built-in analytics surface the insights you need to identify bottlenecks and make data-driven improvements.

For organisations focused on sustainable productivity, Asa.Team also monitors team wellness and detects burnout risk before it becomes a crisis—because true process improvement means creating systems where both the work and the people doing it can thrive.